HG 508 Csőhengerlőgép

HG508 Csőhengerlő

A montalto di castroi képzési helyszínre 13:40-kor tudok érkezni. 16:00-kor távozom majd az állomásról. Ha Ön szerint rendben van, meg tudom csinálni. Szükségem lesz arra, hogy a gyár és a képzési helyszín között elvigyenek.

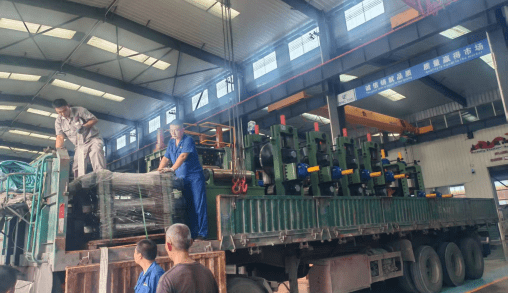

Betöltés: |

Ez a folyamat a tekercs acél felhelyezését jelenti a tekercseltető gépre. csavaró a gép. |

Tekercseltetés: |

Ez a folyamat magában foglalja a tekercs acél felvételét, a tekercs acél meglazítását és kihajtogatását, hogy lapos acélcsíkot állítsanak elő. |

Egyenesítő fej és síkítás: |

Acéltől csíkok fejet lehúzzák a tekercsről, majd betáplálják a síkítógépbe. |

Vágás és tompa hegesztés: |

A folyamat során két fémcsík végeit vágják le, hogy tiszta, egységes éleket kapjanak, majd azokat szilárdan összehegesztik. |

Akkumulátor : |

Ez az anyagfolyam folyamatos szalagjának ideiglenes tárolását jelenti, lehetővé téve a termelővonal megszakítás nélküli működését. |

Hengerlés: |

Ez egy folyamatos folyamat, amely lemezes fémet alakít át egymást követően elhelyezett, párosított hengerek segítségével, melyek mindegyike csupán kis mértékben változtat a formán. Ezeknek a kis formaváltozásoknak az összege egy összetett profil. |

HF hegesztés: |

A folyamat örvényáramokat és bőrhatás jelenségét idézi elő, a hőt pontosan a hegesztett felületeken koncentrálva. Amikor az anyag eléri a plasztikus állapotot, nyomás hatására atomi diffúzió jön létre, amely szilárd test kötést eredményez az alapfém megolvasztása nélkül. |

Keményperem eltávolítás: |

Ez a folyamat a hegesztett cső belső és külső felületén keletkezett hegesztési nyomok és élek eltávolítását szolgálja egy kaparó segítségével. |

Hűtés: |

A hegesztett csövek és a hegesztőgép folyamatos hűtésének folyamata cirkulációs vízzel vagy emulzióval. |

Kalibrálás: |

A kívánt tűrésnek megfelelő kerekességének tökéletesítése. |

Törökfej : |

A cső beállítását jelenti a hegesztést követő hűtés során keletkezett hőfeszültségből adódó görbületek eltávolításához. Általában törökfejes állványok használatával történik. |

hosszra vágás : |

Repülőfűrész használata vagy hidegvágó fűrész a hegesztett cső a kívánt hosszúságúra való vágásához. |

Szállítás: |

A hengeres szállítószalag használatával szállítsa a méretre vágott hegesztett csöveket a rakodóra. |

Raktározás soronként: |

Kézzel a kész csövek rakodását olyan formákba végezze, amelyek a tárolás és a szállítás szempontjából kényelmesek (automatikus, választható) |

Csomagolás: |

Kézi kösse össze a rakodott hegesztett csöveket. (automatikus, választható) |