İmalat Verimliliğini Modern Boru Üretim Sistemleriyle Dönüştürmek

Günümüz rekabetçi imalat sektöründe üretim kapasitesini optimize etmek yalnızca bir avantaj değil – hayatta kalabilmek için bir gerekliliktir. Bir boru üretim hattı imalatta verimlilik ve çıktı potansiyeli açısından daha önce görülmemiş seviyelere ulaşan gelişmiş bir üretim teknolojisi temsil eder. Sektörler sürekli gelişmeye devam ettikçe, ileri düzey boru üretim hatlarının uygulanması, üreticilerin operasyonel kapasitelerini artırmak için oyun değiştirici bir strateji haline gelmiştir.

Modern bir boru üretim hattının entegrasyonu, imalat sürecinizi dönüştürebilir; operasyonları kolaylaştırırken aynı anda kalite kontrolünü artırır ve israfı azaltır. Bu kapsamlı analiz, bu tür gelişmiş sistemlerin üretim kapasitenizi nasıl dönüştürebileceğini ve yatırımın geri dönüşü açısından önemli kazanımlar sağlayacağını açıklamaktadır.

İleri Tüp Üretim Sistemlerinin Temel Bileşenleri

Gerekli Makineler ve Ekipman

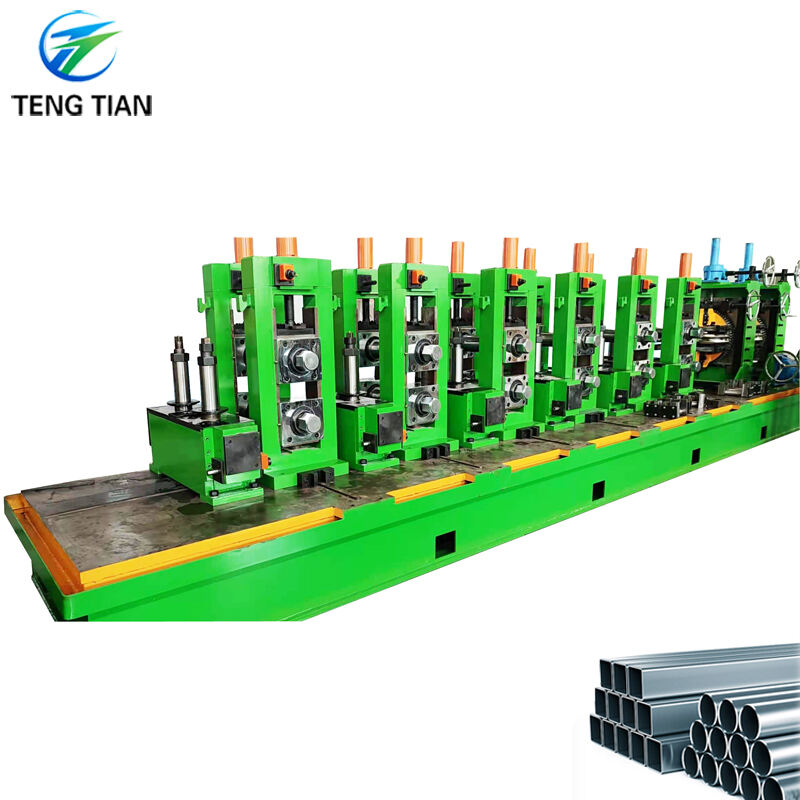

Kapsamlı bir boru üretim hattı, mükemmel şekilde senkronize çalışan birkaç bağlantılı bileşenden oluşur. Süreç, ham madde beslemesini gerçekleştiren açıcı (uncoiler) ile başlar, ardından düz şeritlerin boru şeklinde şekillendirildiği formasyon bölümü gelir. Kaynaştırma istasyonu, kritik bir bileşen olarak, hassas ve dayanıklı dikiş birleştirmesini sağlar; kalibrasyon bölümü ise tam ölçüde spesifikasyonların korunmasını sağlar.

Kalite kontrol sistemleri, üretim bandında tutarlı ürün standartlarını korumak için ultrasonik test ekipmanları ve lazer ölçüm araçlarını içererek tüm hat boyunca entegre edilmiştir. Kesme istasyonu ve uç bitirme ekipmanları temel kurulumu tamamlar, ancak özel üretim gereksinimlerine bağlı olarak ek özel bileşenler eklenebilir.

Otomasyon ve kontrol sistemleri

Modern boru üretim hatları, imalat sürecinin her aşaması üzerinde hassas kontrol sağlayabilmek için gelişmiş otomasyon teknolojilerinden yararlanır. Programlanabilir Mantık Denetleyicileri (PLC'ler) çeşitli bileşenleri koordine ederken, gelişmiş sensörler üretim parametrelerini gerçek zamanlı olarak izler. Bu sistemler, optimal performansı korumak ve hataların oluşma olasılığını azaltmak için hızlı ayarlamalara olanak sağlar.

Endüstri 4.0 teknolojilerinin entegrasyonu, kapsamlı veri toplama ve analiz imkanı sunar; bu da prediktif bakım ve sürekli süreç optimizasyonunu mümkün kılar. Bu düzeyde otomasyon, insan hatasını önemli ölçüde azaltırken genel işletimsel verimliliği artırır.

Verimlilik Faydaları ve Üretim Artışı

Hız ve Verimlilikte İyileşmeler

İyi tasarlanmış bir boru üretimi hattı, üretim hızlarını ciddi şekilde artırırken aynı zamanda kalite standartlarında tutarlılığı sağlayabilir. Malzeme ve özelliklere bağlı olarak modern sistemler dakikada birkaç yüz metre üretim hızına ulaşabilir. Bu da geleneksel üretim yöntemlerine kıyasla önemli bir iyileşmeyi temsil eder.

Üretim sürecinin sürekliliği, parti üretim yöntemiyle ilişkili olan birçok darboğazı ortadan kaldırır. Hazırlık sürelerini azaltarak ve üretim kesintilerini en aza indirgeyerek üreticiler, minimum kesintiyle sürdürülebilir yüksek üretimli operasyonlar gerçekleştirebilir.

Kalite Kontrolü ve Atık Azaltımı

Boru üretim hattında entegre kalite kontrol sistemleri, ürün kalitesinin sürekli olmasını sağlarken malzeme israfını en aza indirger. Gelişmiş izleme sistemleri, gerçek zamanlı olarak sapmaları tespit edebilir ve düzeltebilir; böylece kusurlu ürün üretimini önler. Kalite kontrolde bu proaktif yaklaşım, hurda oranlarını ve buna bağlı maliyetleri önemli ölçüde azaltır.

Modern üretim hatlarının sunduğu hassas kontrol, daha sıkı toleranslara uyulmasını sağlayarak daha kaliteli ürünler ve artan müşteri memnuniyeti ile sonuçlanır. Kalite kontroldeki bu iyileştirmeler, yeniden işleme ve onarımların ihtiyacını azaltarak doğrudan artırılmış üretim kapasitesine katkı sağlar.

Ekonomik Etki ve Yatırım Getirisi

Maliyet Etkinliği Analizi

Bir tüp üretim hattına yatırım yapmak, hem kısa vadeli hem de uzun vadeli finansal etkilerin dikkatli bir şekilde değerlendirilmesini gerektirir. İlk sermaye yatırımı önemli miktarda olabilir; ancak üretim kapasitesindeki artış ve düşen işletme maliyetleri, genellikle cazip getiri oranları ile sonuçlanır. Otomasyon sayesinde birim başına düşen işçilik maliyetleri önemli ölçüde azalır; enerji verimliliği iyileştirmeleri ise işletme giderlerinin düşmesine katkı sağlar.

Modern üretim hatlarıyla malzeme kullanım oranları genellikle artar ve bu da israfın azalmasına ve maliyetlerin daha iyi yönetilmesine yol açar. Sürekli kalitenin sağlanması da garanti taleplerini ve müşteri iadelerini azaltarak ekonomik faydaları daha da artırır.

Piyasa Rekabet Gücü

Modern bir tüp üretim hattı ile üretim kapasitesinin artırılması, üreticilerin piyasa taleplerine daha etkili şekilde yanıt vermesini sağlar. Kalite standartlarını korurken daha yüksek miktarlarda üretim yapma becerisi, genellikle daha iyi piyasa konumu ve artan müşteri memnuniyetine yol açar. Bu yetenek, özellikle sezonluk talep dalgalanmaları veya hızlı büyüme potansiyeline sahip sektörlerde oldukça değerli olabilir.

Modern üretim hatlarının esnekliği, üreticilerin ürün özelliklerini ayarlayarak ya da üretim miktarlarını değiştirerek değişen piyasa gereksinimlerine hızlı şekilde adapte olmalarına olanak tanır. Bu uygumlanabilirlik, günümüz dinamik üretim ortamında önemli bir rekabet avantajı sağlar.

Uygulama Stratejileri ve Dikkat Edilmesi Gerekenler

Planlama ve Entegrasyon

Bir tüp üretim hattının başarılı bir şekilde uygulanması, mevcut üretim süreçlerinin dikkatli planlanması ve değerlendirilmesini gerektirir. Mevcut üretim kapasitelerinin, alan gereksinimlerinin ve iş gücü becerilerinin kapsamlı bir değerlendirmesi hayati öneme sahiptir. Entegrasyon planı, devam eden operasyonlara olası aksamalara çözüm getirmeli ve operasyon personeli için kapsamlı eğitim programlarını içermelidir.

Ekipman tedarikçileriyle planlama aşamasında yakın çalışmak, seçilen sistemin özel üretim gereksinimleriyle ve gelecekteki büyüme hedefleriyle uyumlu olmasını sağlar. Bu iş birliği aynı zamanda kurulum ve devreye alma süreçlerinin daha sorunsuz geçmesine yardımcı olabilir.

Bakım ve Optimizasyon

Bir tüp üretim hattının faydalarını en verimli şekilde kullanmak için etkili bakım protokolleri oluşturmak hayati öneme sahiptir. Önleyici bakım programları, yedek parçaların stok yönetimi ve düzenli sistem optimizasyonu, yüksek performansın sürekliliğine katkı sağlar. Eğitim programları hem rutin bakım prosedürlerini hem de sorun giderme tekniklerini vurgulamalıdır.

Üretim verilerinin sürekli izlenmesi ve analiz edilmesi, işletim parametrelerinin devamlı olarak optimize edilmesine olanak sağlar ve böylece sistemdeki zirve verimlilik seviyesi korunur. Bakım stratejilerinin düzenli olarak gözden geçirilmesi ve ayarlanması, beklenmedik duruşları önlemeye ve ekipman ömrünü uzatmaya yardımcı olur.

Sıkça Sorulan Sorular

Tam bir tüp üretim hattının kurulumu ne kadar sürer?

Bir tüp üretim hattının kurulum süresi genellikle sistemin karmaşıklığına ve saha hazırlık gereksinimlerine bağlı olarak 3 ila 6 ay arasında değişir. Bu süre, ekipman kurulumunu, test süreçlerini ve başlangıç operatör eğitimi aşamalarını kapsar.

Boru üretim hattı hangi tür bakımı gerektirir?

Günlük kontroller, haftalık parça kontrolleri ve planlı önleyici bakım faaliyetleri olmak üzere düzenli bakım işlemleri yapılır. Büyük bakımlar genellikle 6-12 ay aralıklarla, üretim hacmine ve çalışma koşullarına bağlı olarak gerçekleştirilir.

Boru üretim hattı için beklenen yatırım geri dönüş oranı nedir?

Gerçekleşen ROI (Yatırım Geri Dönüşümü), özel koşullara bağlı olarak değişmekle birlikte, çoğu üretici kurulumdan sonra 2-4 yıl içinde olumlu sonuçlar elde etmektedir. ROI'yi etkileyen faktörler arasında üretim hacmi, malzeme maliyetleri, işçilik tasarrufları ve piyasa koşulları yer almaktadır.

Mevcut üretim tesisleri yeni boru üretim ekipmanlarıyla güncellenebilir mi?

Evet, birçok tesis modern boru üretim ekipmanlarıyla güncellenebilir veya retrofit edilebilir. Ancak, mevcut altyapıyla uyumluluğun sağlanması ve devam eden operasyonlarda aksamaya neden olmamak adına dikkatli planlama yapılmalıdır.