Automation and High-Speed Production

Streamlined Manufacturing Processes

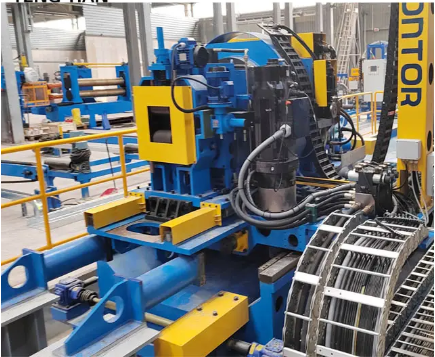

Automation in steel pipe production plays a crucial role in enhancing manufacturing efficiency by minimizing manual intervention. This automation paves the way for continuous operations, reducing the need for stopping and starting the production line. Integrating robotics and automated systems optimizes workflows, significantly cutting down downtimes. Such enhancements are vital for meeting the ever-increasing market demands for steel pipes. In many cases, companies adopting these advanced technologies have reported a staggering increase in production rates by up to 70%. This leap illustrates how embracing automation can transform the production landscape of steel pipes.

Reduced Labor Dependency

The advent of automation in manufacturing steel pipes reduces the dependence on skilled labor, offering a solution to labor shortages and the fluctuations in the workforce. This technological progress decreases the likelihood of human error, particularly in repetitive tasks. Such advancements not only improve safety standards but also contribute to reduced accident rates on the shop floor. Statistical evidence supports this, showing that fully automated plants can cut operational labor costs by approximately 30%. This reduction is not just a cost-saving measure but also a strategic advantage, allowing companies to redirect resources and efforts towards innovation and quality enhancement.

By focusing on automation, manufacturers can navigate the complexities of modern industrial environments more effectively, ensuring sustainability and profitability in competitive markets.

Precision Engineering and Quality Assurance

Advanced Quality Control Systems

In the realm of steel pipe manufacturing, advanced quality control systems are integral to ensuring product integrity and consistency. High-precision machines equipped with such systems are able to monitor and adjust production parameters in real-time, allowing for swift interventions that prevent defects. The integration of AI technologies in these processes further refines efficiency by dramatically reducing defects, thereby elevating product quality to meet industry standards. Industry benchmarks indicate that organizations adopting smart quality control can witness a 50% decrease in rework and scrap rates, showcasing the efficacy of these innovations.

Consistent Output and Reduced Waste

Precision engineering in steel pipe production is crucial for maintaining consistent product specifications, which are central to customer satisfaction across varied applications. Utilizing automated feedback loops allows manufacturers to make on-the-fly adjustments, significantly minimizing variations that contribute to waste. Through these techniques, companies are able to achieve a remarkable reduction in material waste—case studies have revealed reductions of up to 20% in material waste. This not only enhances sustainability but also optimizes resource utilization, marking a significant leap forward in efficient steel pipe manufacturing processes.

Economic and Environmental Benefits

Lower Operational Costs

Automation in the manufacturing sector, including steel pipe making, is key to minimizing operational costs. The integration of robots and automated systems often translates to efficient resource usage, drastically reducing the costs associated with labor and machinery operations. Regular expenses linked with human labor—such as wages, benefits, and training—often surpass the maintenance costs of automated systems. Quantitative analyses across industries have highlighted the economic benefits of automation, with companies realizing reductions in overall operational expenditures by up to 25%. This financial advantage not only fortifies the industry's economic stability but also offers competitive pricing, aligning products with market demand.

Energy Efficiency and Sustainability

Modern steel pipe-making machines have become pivotal in promoting energy efficiency and sustainability within the manufacturing process. These machines are equipped with advanced energy-efficient technologies that help in significantly cutting down energy consumption, thus contributing to better environmental stewardship for companies. When manufacturers adopt sustainable practices during production, they not only improve compliance with regulatory standards but also position themselves as environmentally responsible organizations. Research supports this approach by illustrating that companies embracing these methods achieve up to a 40% increase in energy efficiency. This shift not only enhances operational efficiency but also aligns with the growing global demand for greener production processes, underscoring the vital role of responsible manufacturing in paving the way for a sustainable future.

Advanced Technological Features

Integration of IoT and Smart Monitoring

Integrating the Internet of Things (IoT) into steel pipe manufacturing dramatically enhances process control through advanced monitoring. By enabling predictive maintenance, IoT systems help reduce downtime and improve overall operational efficiency. Smart monitoring systems provide dynamic adjustments based on real-time data to maximize uptime; this capability significantly enhances machine performance and reduces unexpected failures. Reports indicate that companies leveraging IoT technologies experience a decrease in machine failures by approximately 30%, showcasing its impact on reliability and efficiency in manufacturing.

Customization Capabilities

The customization capabilities of modern steel pipe-making machines are a key advantage for manufacturers looking to meet specific market demands. With flexible production systems, these machines allow for greater customization of steel pipes to satisfy diverse client specifications. Such advanced machinery can swiftly switch between different product designs, significantly reducing lead times and boosting customer satisfaction. Feedback from numerous clients indicates a growing preference for customized solutions. This preference not only drives demand but also enhances market competitiveness for manufacturers capable of leveraging these flexible systems.

FAQ

What role does automation play in steel pipe production?

Automation helps enhance manufacturing efficiency by reducing manual intervention and downtime, which leads to increased production rates by up to 70%.

How does automation affect labor requirements in steel pipe manufacturing?

It reduces dependency on skilled labor by minimizing human error and labor costs, which can cut operational costs by about 30%.

How do advanced quality control systems improve steel pipe production?

They ensure product integrity by monitoring and adjusting production parameters in real-time, leading to a 50% decrease in rework and scrap rates.

What are the economic benefits of automation in manufacturing?

Automation can minimize operational costs by up to 25%, offering competitive pricing and increasing economic stability of manufacturers.

Is energy efficiency improved in modern steel pipe manufacturing?

Yes, advanced technologies in modern machines can increase energy efficiency by up to 40%, promoting sustainability.

Table of Contents

- Automation and High-Speed Production

- Precision Engineering and Quality Assurance

- Economic and Environmental Benefits

- Advanced Technological Features

-

FAQ

- What role does automation play in steel pipe production?

- How does automation affect labor requirements in steel pipe manufacturing?

- How do advanced quality control systems improve steel pipe production?

- What are the economic benefits of automation in manufacturing?

- Is energy efficiency improved in modern steel pipe manufacturing?