Blog

-

Why Should You Upgrade to an Automated Tube Production Line?

2025-09-25 09:30:00Transforming Manufacturing Efficiency Through Modern Tube Production The manufacturing landscape is rapidly evolving, and at its forefront is the revolutionary automated tube production line. This advanced technology has fundamentally changed how ind...

VIEW MORE -

How Does a Tube Production Line Ensure Consistent Tube Quality?

2025-09-23 09:30:00Understanding Modern Tube Manufacturing Excellence The tube production line represents the backbone of modern industrial manufacturing, where precision and consistency are paramount. These sophisticated manufacturing systems integrate multiple stages...

VIEW MORE -

Can a Tube Production Line Increase Your Output Capacity?

2025-09-17 09:30:00Transforming Manufacturing Efficiency Through Modern Tube Production Systems In today's competitive manufacturing landscape, optimizing production capacity isn't just an advantage – it's a necessity for survival. A tube production line represen...

VIEW MORE -

Is an ERW Pipe Mill the Right Choice for Your Business?

2025-09-17 07:30:00Understanding the Strategic Value of ERW Pipe Manufacturing In today's competitive industrial landscape, establishing an ERW pipe mill represents a significant strategic decision that can transform your manufacturing capabilities. Electric Resistance...

VIEW MORE -

Auto Spray Paint Line: How It Enhances Coating Efficiency and Uniformity

2025-09-09 10:00:00Revolutionary Advancements in Industrial Coating Systems The evolution of industrial finishing has reached new heights with the integration of auto spray paint lines into manufacturing processes. These sophisticated systems represent a quantum leap i...

VIEW MORE -

Choosing the Right H Beam Production Line for Your Fabrication Needs

2025-09-03 09:30:00Understanding Modern H Beam Manufacturing Solutions The evolution of steel fabrication has brought sophisticated h beam production line technologies to the forefront of industrial manufacturing. These advanced systems represent a significant investme...

VIEW MORE -

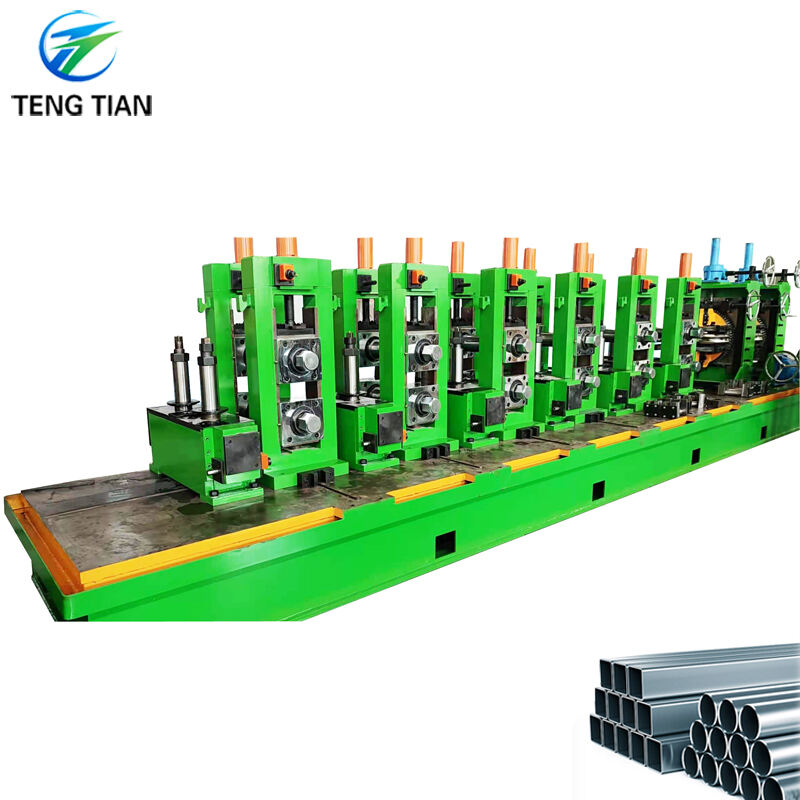

Why Is a Steel Pipe Making Machine Essential in Pipe Manufacturing?

2025-08-29 11:00:30The Revolutionary Impact of Modern Steel Pipe Manufacturing Technology The steel pipe manufacturing industry has undergone a dramatic transformation with the introduction of advanced steel pipe making machines. These sophisticated pieces of equipment...

VIEW MORE -

How Does a Steel Pipe Making Machine Improve Manufacturing Efficiency?

2025-08-21 11:00:12Revolutionizing Industrial Production Through Advanced Pipe Manufacturing The steel pipe making machine stands as a cornerstone of modern industrial manufacturing, transforming the way we produce essential components for construction, oil and gas, an...

VIEW MORE -

Top Features to Look for in a Modern Steel Pipe Making Machine

2025-08-15 09:00:47Essential Capabilities of Advanced Steel Pipe Manufacturing Equipment Modern manufacturing demands have revolutionized the way we approach steel pipe production. Today's steel pipe making machines combine cutting-edge technology with precision engine...

VIEW MORE -

What Are the Key Advantages of Using a Steel Pipe Making Machine?

2025-08-07 14:00:31Revolutionizing Metal Manufacturing with Modern Steel Pipe Production The manufacturing industry has witnessed remarkable transformations over the decades, and one of the most significant advancements has been the development of the steel pipe making...

VIEW MORE -

How to Choose the Best Steel Pipe Making Machine for Your Factory?

2025-08-01 10:00:57Optimizing Your Manufacturing Capabilities with Modern Steel Pipe Production Equipment The manufacturing industry continues to evolve rapidly, and selecting the right steel pipe making machine has become crucial for factory success. Modern production...

VIEW MORE -

How to Choose the Right Direct Forming Tube Equipment for Your Factory?

2025-07-29 10:03:33Understanding Direct Forming Tube Equipment Basics Direct Forming Tube Process Fundamentals Direct forming is a streamlined manufacturing process used to produce tubular products, notably marked by its ability to shape steel strips directly into squ...

VIEW MORE