Blog

-

What are the types of steel tube making machines?

2025-05-07 15:00:00Electric Resistance Welding (ERW) Machines ERW Process and Key Applications Electric Resistance Welding (ERW) is a pivotal process in steel manufacturing, employing electrical current to heat metal for creating robust welded joints. This process is ...

VIEW MORE -

What industries use steel tube making machines?

2025-05-01 15:00:00Construction and Infrastructure Development Structural Steel Tubes for High-Rise Buildings Structural steel tubes play a vital role in providing the necessary strength and stability to high-rise buildings, particularly in seismic zones where safety ...

VIEW MORE -

Steel Pipe Making Machine Maintenance: Tips and Tricks

2025-04-27 16:00:00Essential Steel Pipe Making Machine Maintenance Checklist Daily Cleaning Procedures for Debris Removal A crucial aspect of maintaining steel pipe-making machines is regular cleaning to prevent debris accumulation. Key areas where debris is likely to...

VIEW MORE -

Key Advantages of Modern Steel Pipe Making Machines

2025-04-20 16:00:00Automation and High-Speed Production Streamlined Manufacturing Processes Automation in steel pipe production plays a crucial role in enhancing manufacturing efficiency by minimizing manual intervention. This automation paves the way for continuous o...

VIEW MORE -

The Future of Steel Pipe Making Machines in 2025

2025-04-13 16:00:00Technological Innovations Shaping Steel Pipe Making Machines by 2025 AI-Driven Precision in Pipe Manufacturing Artificial intelligence (AI) is revolutionizing precision and efficiency in the steel pipe manufacturing industry. By leveraging AI techno...

VIEW MORE -

Top 5 Features to Look for in a Steel Pipe Making Machine

2025-04-07 16:00:00Production Capacity and Efficiency in Steel Pipe Making Machines Evaluating Throughput Rates for Industrial Demands Throughput rates are a crucial factor in ensuring that steel pipe manufacturing meets production goals while satisfying industrial de...

VIEW MORE -

How Steel Pipe Making Machines Revolutionize Production

2025-04-01 16:00:00Historical Evolution of Steel Pipe Production The Industrial Revolution and Early Challenges The beginning of steel pipe production was closely tied to the Industrial Revolution, a period marked by significant advancements in manufacturing. During t...

VIEW MORE -

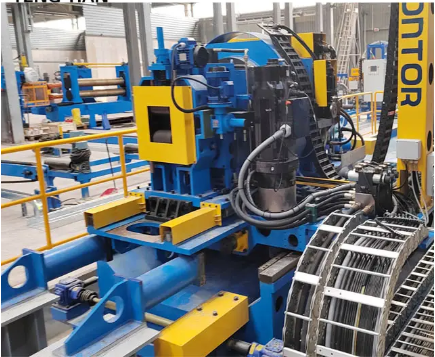

The Automatic Tube Mill: A Guide to Enhancing Your Production Line

2025-03-25 16:00:00Core Components of an Automatic Tube Mill SystemSlitting Machines: Precision Material PreparationSlitting machines are pivotal in the initial stages of tube milling as they prepare the raw materials by accurately cutting them to the designated width....

VIEW MORE -

The Automatic Tube Mill: A Step-by-Step Production Process

2025-03-19 16:00:00Key Components of an Automatic Tube Mill System Uncoiling and Straightening Mechanisms Uncoiling and straightening mechanisms are vital in preparing metal coils for the tube mill process. The uncoiling apparatus plays a crucial role by gradually ...

VIEW MORE -

The Automatic Tube Mill: Ensuring Quality and Consistency in Pipes

2025-03-13 16:00:00Core Components and Operational Workflow of Automatic Tube Mills Forming and Shaping Processes The forming and shaping processes are among the initial stages in the production of tubes using automatic tube mills. These steps involve the transformatio...

VIEW MORE -

The Automatic Tube Mill: A Revolution in Steel Pipe Manufacturing

2025-03-07 16:00:00Transforming Steel Production with Automation Steel pipe manufacturing has long been an essential industry for construction, energy, and transportation sectors. The advent of the Automatic Tube Mill has introduced a new era in the production process...

VIEW MORE -

The Automatic Tube Mill: A Cost-Effective Solution for Pipe Production

2025-03-01 16:00:00Understanding Automatic Tube Mills in Modern Pipe ProductionAutomatic Tube Mills are indispensable in today's pipe manufacturing sector due to their ability to enhance both efficiency and precision. By utilizing automated processes, these mills minim...

VIEW MORE