Introduction

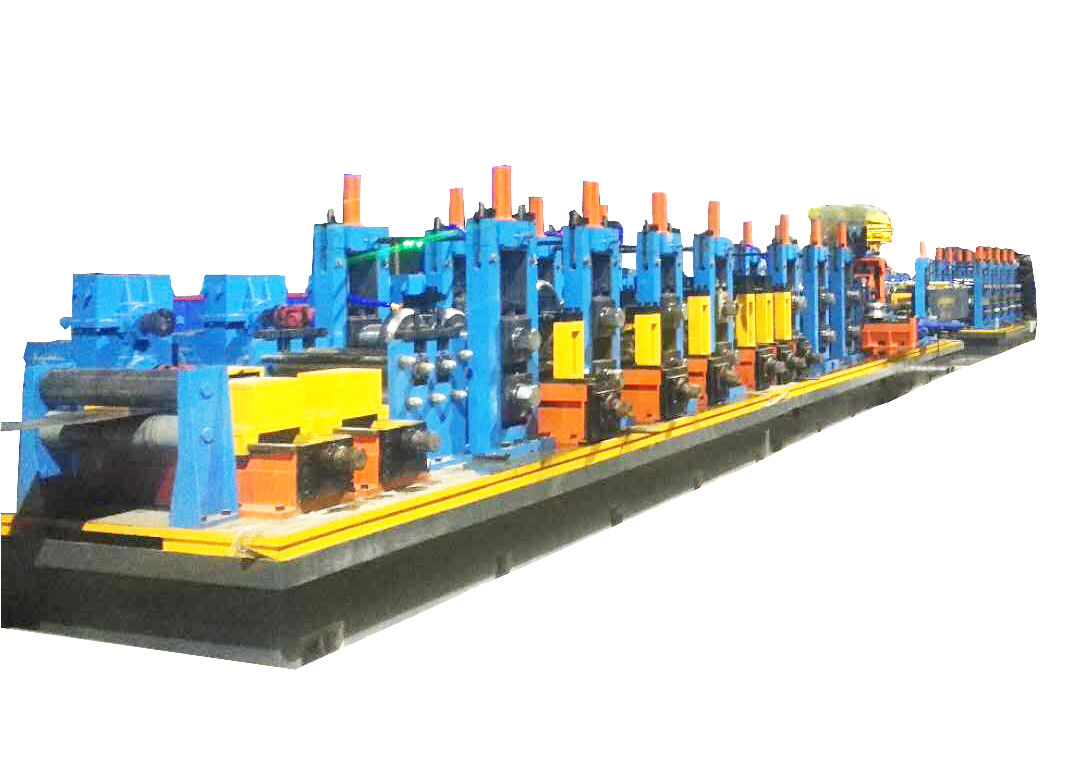

C/Z Semi-automatic Purlin Interchange Production Line

The semi-automatic C/Z-type purlin machine can produce various specifications of C/Z-type purlins by using the same set of equipment through semi-automatic simple stepless adjustment, and there is no need to replace the forming rollers when changing specifications. The production process adopts an automatic control method, which can automatically punch, cut and form according to the input parameters such as purlin length, longitudinal hole distance and quantity.

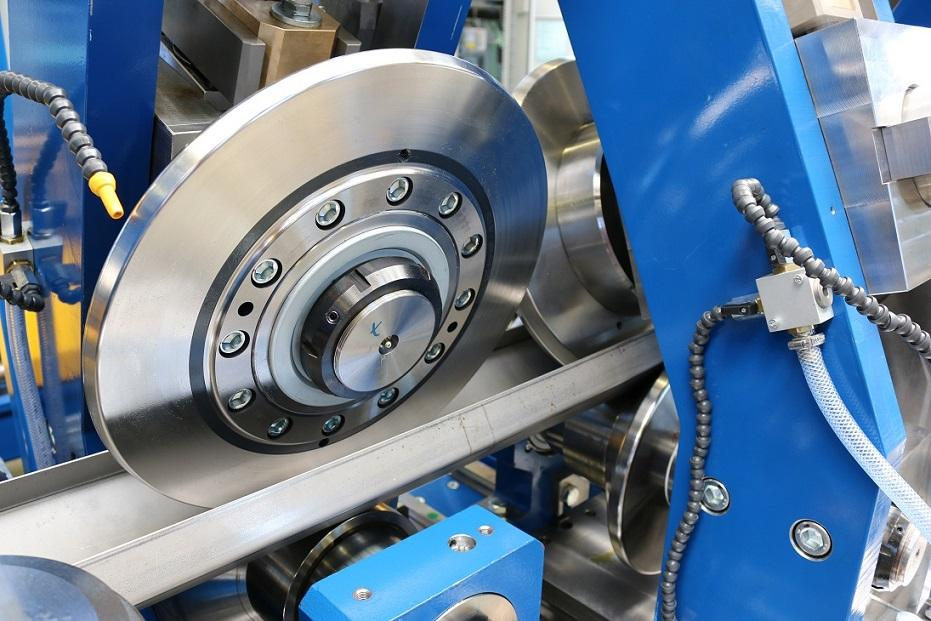

C/Z purlin is composed of guide, leveling device, roll forming machine with quick changeover, 2 hydraulic punching devices, hydraulic stepless adjustment and cutting device, electric control system, hydraulic system and so on.

The main drive of the whole line forming adopts a geared motor plus frequency conversion control, and the speed control, fixed length and positioning control are accurate and reliable.

The whole machine has beautiful appearance and high production efficiency (forming speed reaches 20m/min).

Technical Parameters

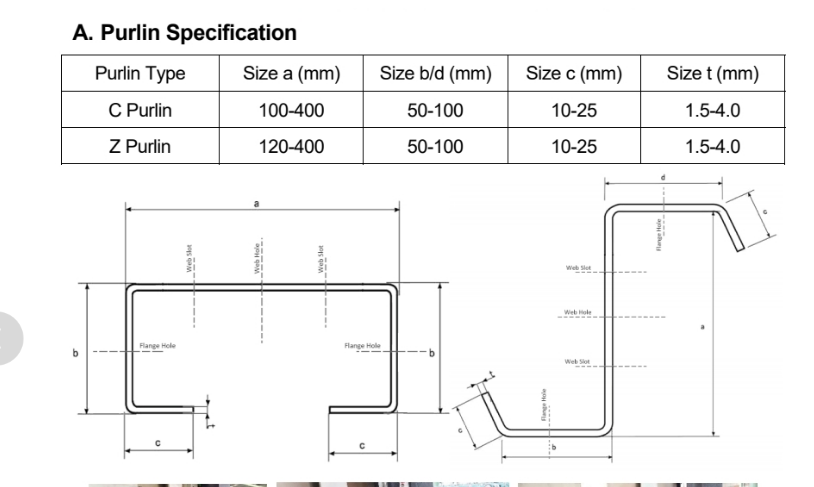

1.C/Z/ Product size:

2. Processing workpiece thickness: 2~4mm

3. Horizontal adjustment range of punching hole distance: 45~650mm

4. Maximum forming speed of purlin: 20m/min

5. Installation form: adopt 125+140 archway

6. Roller table form: split roller table on both sides, spindle plug-in drive

7. Roll material: bearing steel, finished after quenching

8. Spindle material: high-quality No. 45 steel quenched and tempered

9. Main shaft diameter: 105mm (the shaft diameter of the inserted part is 75mm), the final design shall prevail

10. Main motor power: 30KW

11. Total motor power for host width adjustment: 2X0.75KW+1X1.5KW=3KW

12. Drive form: Z230 gearbox

13. Number of forming channels: 18 channels

14. Punching, cutting: hydraulic drive, punching after forming, cutting after forming

15. Motor power of hydraulic station: 11KW, with accumulator

16. Die, cutter material: Cr12 quenching treatment

17. Electric control system: The whole machine adopts industrial computer PLC frequency conversion control